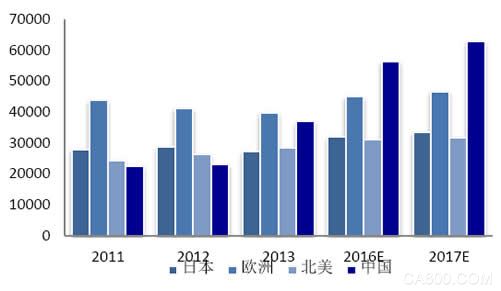

Trend chart of the scale of China's industrial robot market

The 16th Asia Pacific Automation and Instrumentation Exhibition was held in Suzhou on May 12th. The exhibition is themed "Strengthening Intelligent Applications and Promoting Industrial Upgrading". While showcasing the latest automation related technology products at home and abroad, it focuses on highlighting application solutions that are in line with the characteristics of Chinese enterprises, in order to promote the popularization of industrial automation, intelligent technology, and advanced instrumentation technology in various industries in China.

Automation technology refers to the collective term for information processing and process control of machine equipment that achieves measurement, manipulation, and other expected goals without the need for direct human intervention. Industrial automation is an important symbol of modern industry. Through automation technology, industrial enterprises can achieve multiple goals such as improving production efficiency, improving product quality, saving labor costs, reducing consumption, and ensuring safety.

As the growth of China's labor force slows down, the proportion of labor force to the total population is also rapidly declining. In the future, China will face a shortage of labor force, and the demographic dividend will also disappear. In this context, the most effective method currently is to upgrade and transform the automation of the manufacturing industry. Automation and digital equipment can significantly reduce the labor force engaged in production, and the proportion of labor force in the total production cost will become smaller and smaller. In recent years, domestic enterprises have begun to layout the automation equipment industry, and the scale of China's automation market has been increasing year by year. The installation of industrial robots has shown rapid growth, with a compound annual growth rate of 39%.

Data chart: Global robot sales in various countries from 2011 to 2017

Compared with traditional manufacturing, automation equipment has advantages such as precision, automation, graphics, intelligence, visualization, and multimedia. After years of development, China's equipment manufacturing industry has formed a comprehensive, large-scale, and technologically advanced industrial system. Intelligent manufacturing equipment, as a key development in the high-end equipment manufacturing industry, will achieve significant development and widespread application with the continuous adjustment and upgrading of industrial structure and the strong promotion of supportive policies, and is expected to rebuild the competitive landscape of the manufacturing industry.

In terms of policies, in March of this year, the Ministry of Industry and Information Technology issued a notice on carrying out the 2016 Special Action for Intelligent Manufacturing Pilot Demonstration and an implementation plan for the 2016 Special Action for Intelligent Manufacturing Pilot Demonstration, clarifying the specific goals of the special action and deploying the specific work for 2016. In April, the Ministry of Industry and Information Technology and the National Development and Reform Commission jointly released the "Development Plan for the Robot Industry (2016-2020)", proposing a five-year overall goal for industrial development. In addition, the State Council released the "Standardization and Quality Improvement Plan for Equipment Manufacturing Industry" in April, requiring coordination with "Made in China 2025" and promoting standardization in key areas. The introduction of a series of supporting plans will vigorously promote the rapid development of intelligent manufacturing related industries, and the pace of transformation and upgrading of China's manufacturing industry will accelerate.